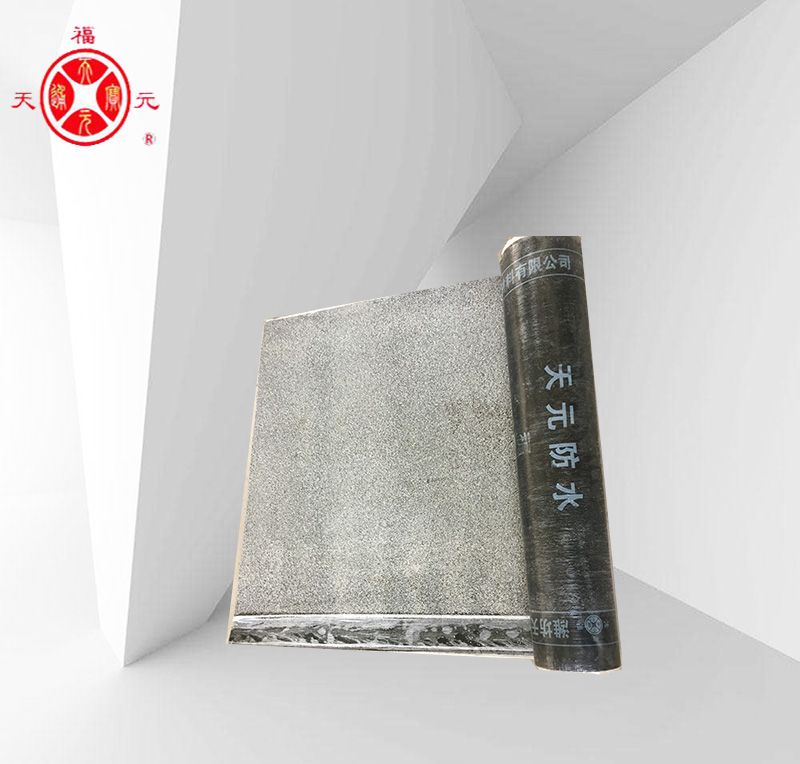

Cement-based Permeable Crystalline Waterproof Coatings

Product introduction:

Cement-based penetrating crystalline waterproofing coating (CCCW) is a kind of light gray powder waterproofing material, which is green, non-toxic, tasteless, pollution-free and rigid waterproofing material. It is based on inorganic materials such as Portland cement and quartz sand and dried with active compounds and other auxiliary materials. It contains abundant active substances. After interaction with water, the active substances in the material permeate into the concrete with water as the carrier, and form crystals insoluble in water, blocking the capillary channels, thus making the concrete compact and waterproof. Cement-based permeable crystalline waterproofing coating has dual waterproofing properties: it has the same waterproofing effect on both the upstream and the back water surfaces, and can be used in waterproofing projects of subway, tunnel, road and bridge, reservoir, culvert, basement floor and inner and outer walls of industrial and civil buildings, and leak-proofing projects of building roof, outer walls and various underground buildings. And all structural defects maintenance of concrete construction facilities. Although the solidified material is rigid, it will not be brittle and cracked, especially suitable for waterproof projects with water plugging.

Product characteristics:

(1) Excellent waterproof capability

(1) Extremely strong water pressure resistance, long-term strong water pressure.

(2) Extremely strong permeability: put it outdoors for half a year, the penetration depth is 100-150 mm.

(3) Extremely long-term self-repairing waterproof ability: cracks less than 0.4mm can be self-repairing

(2) It has the unique ability of breathing, anti-corrosion, aging resistance and steel bar protection.

The material can keep the normal air permeability inside the concrete structure, and the road is dry and not wet. At the same time, it can block the passage of water molecules.

(2) The material has the ability to resist chemical corrosion.

(3) The material has aging resistance and radiation resistance.

(4) After the concrete is treated with this material, it can improve the protection ability of concrete to steel bar, and it can also prevent the peeling, weathering and other damage caused by freezing and thawing.

(3) Environmental protection, non-toxic and pollution-free.

(4) Excellent compatibility with other materials. The material can also be used in concreting with cement.

(5) Simple construction and labor saving.

(6) Low temperature resistance. No cracking, peeling and no change.

Construction method:

Scraping method

When mixing materials, attention should be paid to mixing evenly. There should be no dry material balls in the slurry.

During construction, the slurry prepared according to the requirements is evenly coated on the foundation which needs waterproof. In waterproofing construction on the water-front surface, the amount of water should be increased slightly because of the unpredictable seepage location, so as to improve the anti-seepage ability of waterproofing coating as far as possible, and pay attention to the treatment of honeycomb base surface. When the backwater surface is constructed, the small leakage is easy to detect, and the leakage should be plugged before the waterproof construction.

Routine dosage: SN material 1.3-1.5kg/, coating thickness: 1.0-1.2mm. Construction requires one coating. Attention should be paid to the cleaning and wetting treatment of the coated base surface (fully wet, but not clear water). If it is found that the local base surface is too dry in the construction process, it must be re-wetted.

Brushing method

General requirements according to water: SN material = 2:5 (mass ratio) stirring to thick paste. Mixed slurry must be able to paint a certain thickness.

Routine dosage: SN material (> 1.0kg/), coating thickness: 0.8-1.2mm. Construction requires two or more coatings. During construction, it is also necessary to pay attention to the cleaning and wetting treatment of the coating base surface. The coating exposed to sunlight can last for 1-2 days and be wetted with clean water.

Spraying method

Routine dosage: SN 0.8-1.2 kg/, coating thickness: 0.8-1.2 mm.

| Prev:Delivery site | Next:Delivery site |